The call from society is becoming louder: Politics needs to do more to protect the climate. Photovoltaics – the conversion of sunlight into electrical energy – is undoubtedly an important component of the energy revolution. Photovoltaics already contribute a significant proportion of the energy mix. PV modules with a nominal output of 54 GW had been installed in Germany by the end of 2020, spread over two million installations. In 2020, they generated 50.6 TWh – 9.6% of Germany’s gross power consumption. On sunny days, PV power can at times cover two-thirds of momentary power consumption. Thanks to the rapidly falling module prices, new megawatt installations generate electricity for 3 – 5.5 cents/kWh. For small rooftop installations, this is slightly higher at 6 – 11 cents/kWh, but overall they are already more cost-effective than fossil power plants. This development is likely to continue in the long term, even though module prices have risen recently due to supply bottlenecks as a result of the corona crisis. These facts show the following trends:

Solar projects are becoming ever larger

Due to the lower generation costs, large-scale plants have a price advantage.. A look at Austria shows that not just the cost benefits support larger installations; the country’s ambitious expansion targets simply cannot be achieved with small installations. Austria is therefore investing on large PV parks, such as in Schönkirchen-Reyersdorf north-east of Vienna. In 2020, Austria’s largest free-standing photovoltaic installation came into operation. It consists of 34,600 modules covering an area of 13.3 hectares, which is roughly the size of 18 football pitches. They produce a combined output of 11.5 megawatts and generate almost 11 gigawatt hours of electrical energy per year, which equates to the consumption of 3,400 households.

But that’s peanuts compared to the world’s largest installations. The Saemangeum project in South Korea has built three PV parks each with a peak output of 99 MW. The records are falling thick and fast almost every month. Bhadla Solar Park in India is currently the number one with 2245 MW and an area of 57 square kilometres, which equates to around 8000 football pitches.

Resilience is becoming more important

The flood in western Germany in mid-July may just have been a taster: Climate experts anticipate an accumulation of extreme weather events in the future. This has an impact on the construction and maintenance of photovoltaic installations. UV radiation is likely to increase, as are wind speeds and hail. The modules, as well as the electrical connection systems, have to withstand this. And if an installation is destroyed, it should be rebuilt as quickly as possible. This requires logistics capable of building up new generation capacities within days, if not hours. The same goes for natural disasters such as earthquakes or volcanic eruptions.

As a result, suppliers need to have all common components for constructing a PV installation available from stock in many regions of the world so they can be quickly replaced on site in the event of an emergency. Many supply chains have collapsed during the corona pandemic. For example, there are currently bottlenecks in the PV industry when it comes to delivering modules, but also accessories such as module frames or electronic components for the inverters. Companies with resilient supply chains have an advantage here, which can also be helpful in dealing with customs formalities.

Photovoltaics are becoming more efficient

This does not mean the efficiency of the PV modules themselves, which has been increasing for decades and is always hitting new records – and will in the future, too. Rather, it refers to efficiency in production, installation and disposal of the modules. For monocrystalline PV modules, CO2 emissions have been calculated at 35 to 57 grams per kilowatt hour, which is primarily generated in production. This value is far below that of fossil energy generators and is dropping steadily, not least because solar power makes the energy mix cleaner and thus reduces emissions during production. In Europe, there is also an obligation to take back solar modules at the end of service. Large parts of the modules, such as aluminium frames and glass, are recycled.

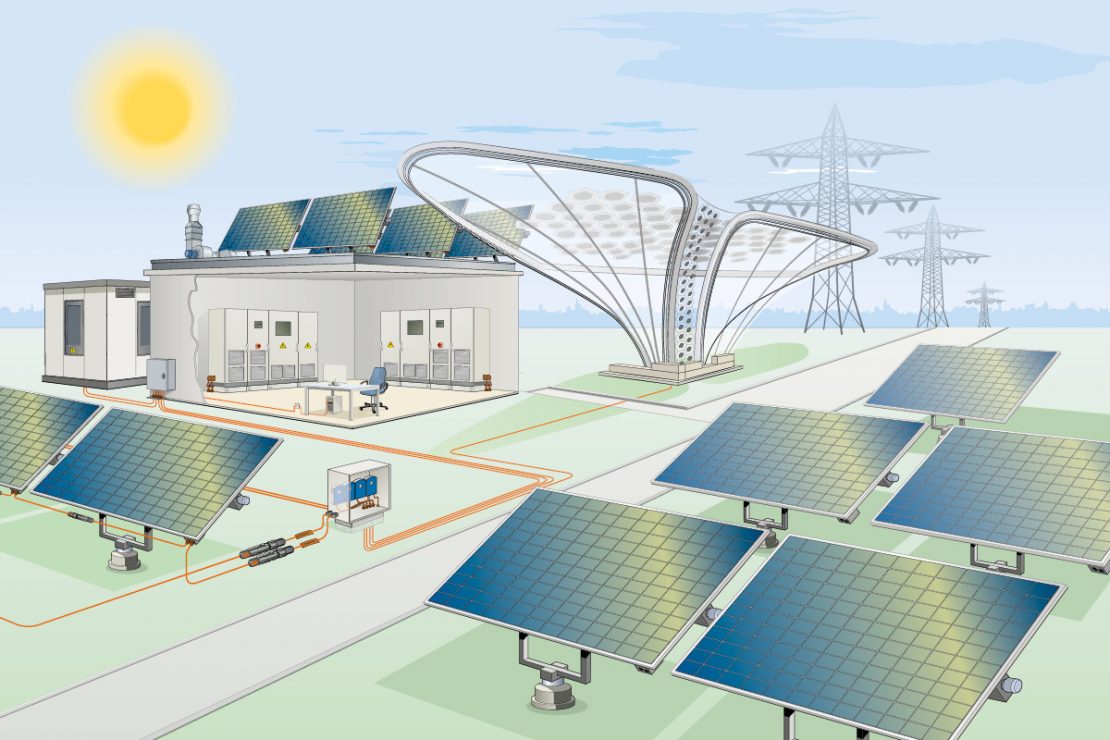

There is further saving potential during installation, especially with large installations. Thousands of identical modules are installed, always with the same spacing, allowing fitters to use assembled cables of the correct length that they simply have to plug in. This saves time and rules out defects that can never be completely eliminated during manual assembly on the construction site.

Grids and storage systems are becoming upgraded for renewable energy

When the sun shines, photovoltaics already cover up to two-thirds of momentary power consumption in Germany. In bad weather, other renewable generators such as wind energy have to deliver, or energy storage systems switch in. There are dozens of ways to do this, from storage in electric vehicle batteries to mechanical pumped storage systems, through to hydrogen – the beacon of hope. As this makes the energy grid more decentralised, it needs to be expanded and above all, it needs to be made smarter.

Photovoltaic systems are becoming more diverse

Either on the existing roof or on the meadow – these were previously the options for constructing PV installations. However, house roofs are limited and solar power generation competes with other uses of open spaces. Several other options have developed over the past few years:

- Facade-integrated PV: Here the idea is that a house needs walls, windows and roof bricks anyway, and solar modules can be integrated right there.

- Agri-PV: Germany has almost 17 million hectares of arable land. Examples from other countries show that PV installations can help maintain fertile soil for shade-loving plants and create diverse biotopes – and even provide pasture for sheep.

- PV on roads: Here, the modules could be integrated into noise barriers or even to cover the road surface. On railway lines, modules could be laid on the sleepers between the rails. The relevant tests are promising, but some authorities have their difficulties when it comes to approval.

- Floating PV: A floating solar park is to be built on the Indonesian island of Batam from 2022. It is intended to produce 2200 MW and cover around 16 square kilometres on the Duriangkang reservoir. Fraunhofer Institute for Solar Energy (ISE) estimates that 2.74 GW can be economically generated in Germany using floating PV. Particularly lakes from closed-down underground mining are candidates. On a flooded gravel pit in Weeze in the Lower Rhine region of Germany, a gravel plant operator has released a 150 x 50 metre solar island with 750 kW for self-supply.

The cables used in photovoltaic installations like these not only need to withstand wind, weather and UV radiation. In future, they may be permanently underwater (floating PV), exposed to increased vibrations (PV on rails) or have to disappear as inconspicuously as possible behind a glass facade.

LAPP is in a good position

These and some other trends will shape the photovoltaics market over the coming years. LAPP is well equipped for this. The company offers a broad portfolio of components for connection technology. LAPP connection systems are used in the photovoltaic installations in Schönkirchen-Reyersdorf and Saemangeum. The cables from the global market leader in connection technology are also used in the largest solar park in the Dominican Republic and large solar installations in South Africa. With ÖLFLEX® CONNECT, the company offers assembled cables for faster installation, which simply need to be plugged in by the fitters on site.

But LAPP is not just a much sought-after partner with its product portfolio, but also with just-in-time construction site logistics; and with global delivery processes, LAPP is ready to respond to global demands. The company is increasingly assuming a leading role in planning and managing large projects, such as the construction of a high-voltage line through the city centre of Braunschweig (Brunswick), Germany, where LAPP acts as the general contractor. LAPP is also expanding its expertise in other areas of renewable energy, such as major wind energy projects or the construction of energy storage systems. The focus of the portfolio on sustainable sectors and the associated project support reinforce LAPP’s claim to offer one-stop-shop solutions.